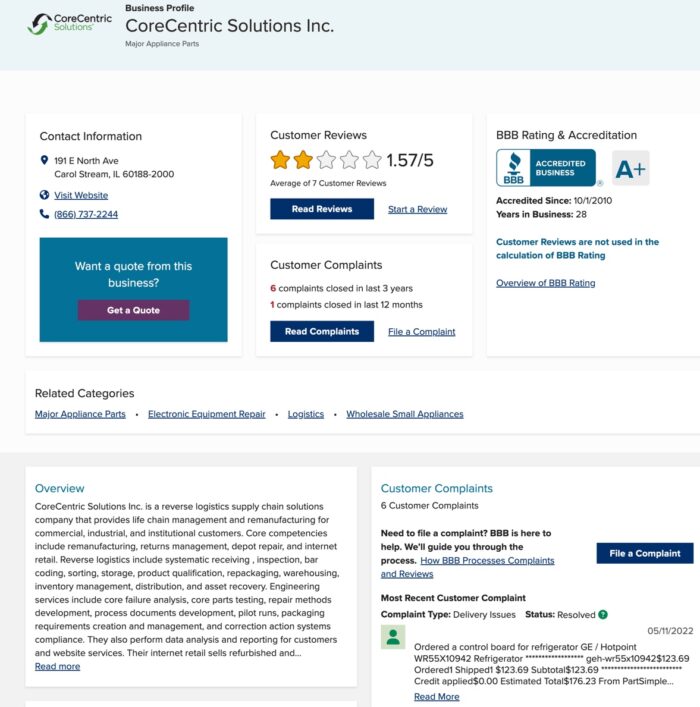

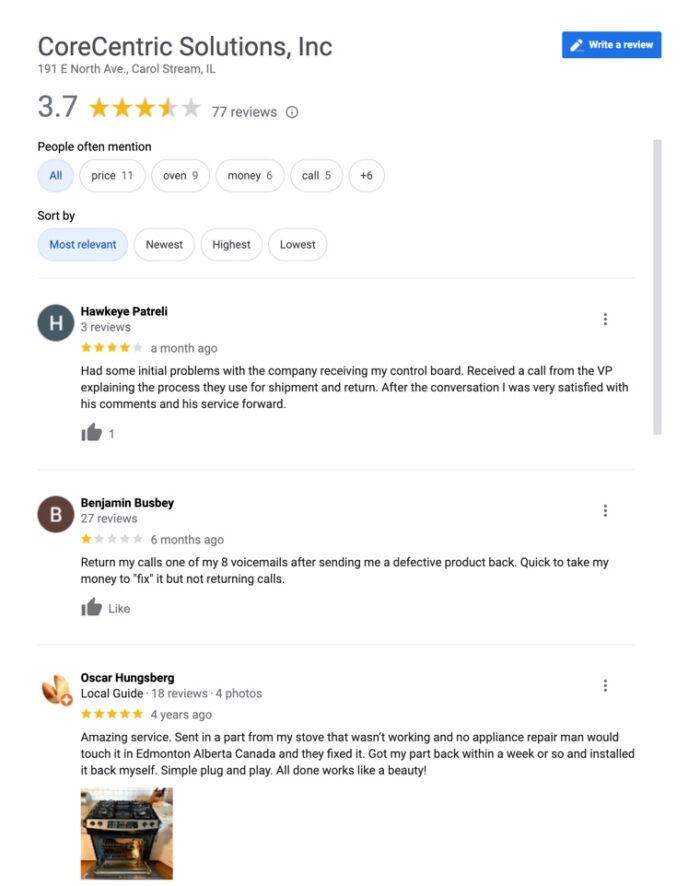

Circuit Board Remanufacturing and Rebuilding First a bit of history of the appliance repair world. In the past 10 years circuit board remanufacturing or repairing has evolved from an insignificant business in to a major factor in the appliance repair world. Why did this happen? But first to explain what exactly is the appliance circuit board remanufacturing business? You are probably aware of the remanufacturing arena in the automotive world where you get a partial credit on the purchase price of a automotive power steering pump or a master cylinder by returning the old part known as a core. This procedure has been around for a long time. Companies were able to sell remanufactured automotive parts by rebuilding the old units and reselling them to the distributors. In the automotive world today you have three choices, 1) you can buy the original part from Toyota at a premium price, 2) you buy a brand-new part from NAPA who subcontracts to a trusted manufacturer or 3) you can get a remanufactured part from a different group of subcontractors. All the big auto parts companies offer the second two options. I have been repairing appliances since 1970 and have seen use of computer boards evolve. Computer boards entered the appliance world through microwaves around 1980. Before too long computer boards started appearing in ovens and ranges and were soon used in every major appliance. As these new appliances aged the manufacturers discontinued certain low-volume parts. Control circuit boards did not make the cut. A knowledgeable source told me long time ago that the manufacturers would make a certain number of major components such as transmissions or circuit boards. When the components ran out, they did not manufacturer a new batch. It was simply not in their best interest because they preferred that the customers be forced to buy a new appliance. This practice makes perfect sense. Of course remanufacturing experts crept into the appliance repair world and started offering a service similar to that of the automotive industry. Some companies in that world claim to be much older but the computer board remanufacturing world really started to take off about 2010. Many of the larger players repair computer boards on all sorts of equipment from vacuum cleaners to excavators. It appears to me that computer boards are used in the automotive world and that the appliance repair circuit world is much smaller. It is interesting to note that often computer boards sold by the large appliance parts distributors who represent the national manufacturers such as Whirlpool and Electrolux are often selling parts remanufactured by a subcontractor. A core credit is offered just like in the automotive industry. This policy enables the manufacturers to maintain a needed inventory of parts for their customers without remanufacturing the parts themselves; they get the best of both worlds. Who are the players in this young industry? Following is a list and analysis of what I have found: CoreCentric Solutions Inc. Corecentric Solutions in CarolStream IL, is the big gun in the appliance circuit board remanufacturing business. They have grown very rapidly in the last 10 years and are now doing the remanufacturing for Whirlpool and General Electric. In the last few years they have opened a store called Parts Simple where they sell remanufactured parts made from cores that they have collected from around the country. My son and I have used their services for long time and have been very pleased with the quality of their work. However in the last year we have begun to have problems. Some of the computer boards that we have sent in for repair have come back flawed and did not work when they were installed in our customers' appliances. Non-working boards is not a large percentage of the repaired boards, but the problem has become very irritating and Corecentric has gotten so large that it is essentially impossible to talk to anyone there who is able to help solve these irritating problems. Added to that irritation a flawed rebuilt board must be shipped back-and-forth at our expense. Based on posted reviews other customers are having similar problems. Consequently my son Reid suggested that we begin doing our own in-house repairs of the computer boards and start offering the service to others. As an electrical engineer, I have found this challenge interesting. Following are two recent reviews :

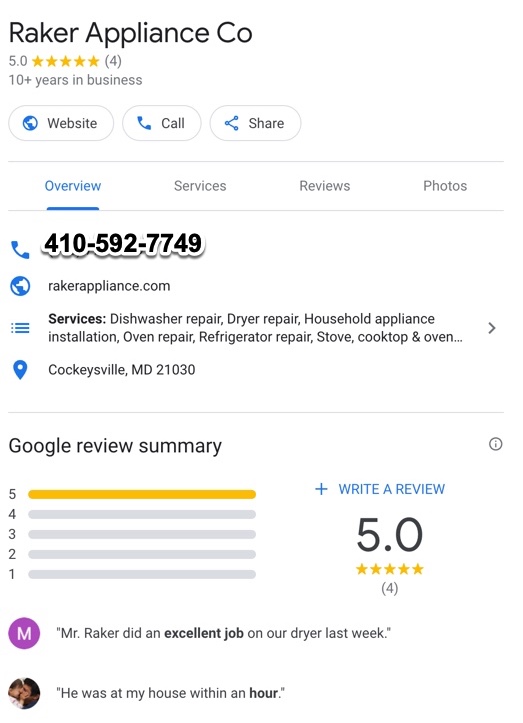

Uncle Harry Appliance Repair Training and Repair Services My business was started in 1968 and is now taking care of our second generation of customers. My son took over the business in 2012 and now has three technicians working for him in the Baltimore area. I serve as backup pinch-hitter when difficult problems arise among his men or they need specific training in certain areas - usually electrical.I have been running a school training men how to start and run a home appliance repair business since 1997 and then coach them to succeed. We now offer computer/circuit board repair for past students, appliance repair technicians and talented individuals. We stress customer service above all else. Harry D. Raker BSEE

Circuit Board Medics Circuit Board Medics, in Greenville SC, another circuit board remanufacturer, is about 1/10 the size of Corecentric and seems focused on automotive, commercial truck, RV and industrial equipment. They have great reviews. We have not personally used them but some of our students have and were satisfied.

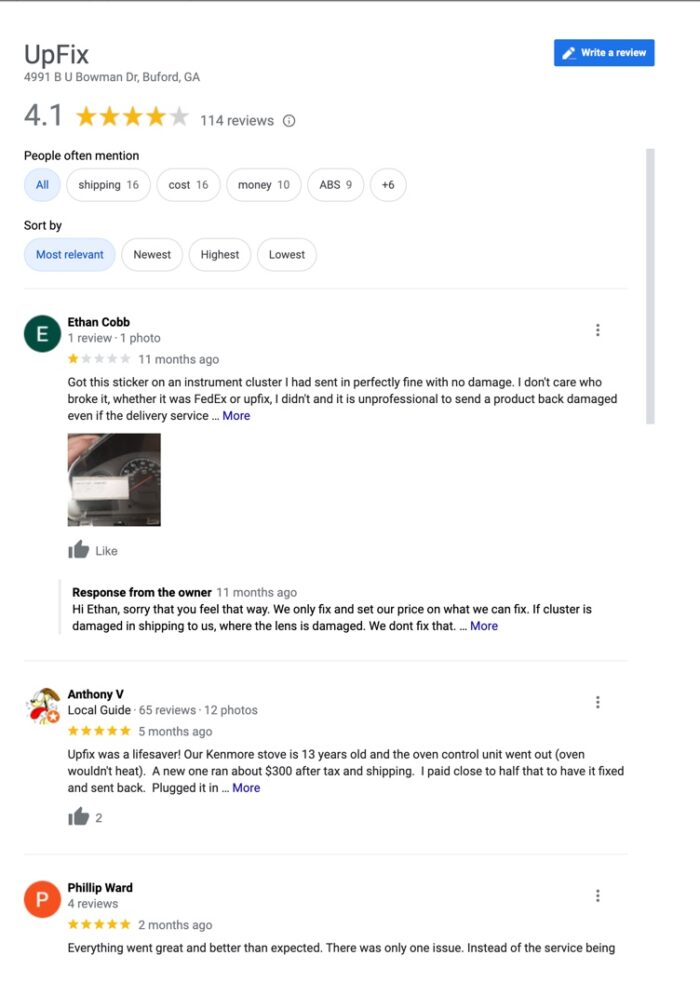

Up Fix Up Fix, located in Buford GA, is also focused on the automotive and industrial area like Circuit Board Medic, but does not have as clean a reputation. They are a bit cheaper but have poor reviews.

There are a few more small players, some advertising on EBAY who don't seem nearly as professional as the preceding ones. When it come to disabling an appliance, packing and shipping the part, waiting and reinstalling it, the last thing a tech wants is "failure to launch". It's not about money, it's all about service! Harry D. Raker BSEE 800-958-4430 Harry@RakerApplianceRepair.com